Ultrasonic thickness gauges provide non-destructive measurements, sending sound waves through materials to determine thickness without altering surfaces. They offer superior precision and efficiency compared to traditional methods in industries like automotive bodywork, where they streamline processes, maintain quality, and ensure accurate thickness assessments for diverse materials, critical for lightweight structural integrity and design standards.

In the realm of precision measurement, ultrasonic thickness gauges offer a game-changing alternative to traditional manual tools. This article explores the myriad benefits of adopting these advanced devices, beginning with their non-destructive measurement advantage, which preserves integrity while providing accurate results. Enhanced precision and efficiency are cornerstones, ensuring swift and reliable data acquisition. Furthermore, their versatility spans diverse applications and material compatibility, making them indispensable across industries.

- Non-Destructive Measurement Advantage

- Improved Precision and Efficiency

- Versatile Applications and Material Compatibility

Non-Destructive Measurement Advantage

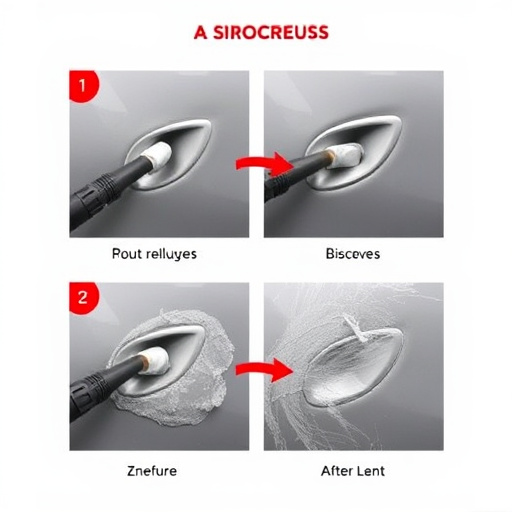

One significant advantage of ultrasonic thickness gauges over manual tools is their non-destructive measurement capability. Unlike traditional methods that may cause damage to the material being measured, such as frame straightening or auto painting processes, ultrasonic thickness gauges send high-frequency sound waves through the material and measure the time it takes for the echo to return. This method ensures no alteration or harm comes to the surface, making it ideal for quality control in industries like car bodywork.

This non-invasive approach allows for accurate thickness measurements without leaving any traces on the product. It’s particularly valuable in situations where precision is key and preserving the integrity of the material is essential, ultimately streamlining production processes while maintaining product quality.

Improved Precision and Efficiency

Using an ultrasonic thickness gauge offers a significant advantage over traditional manual measurement tools in terms of precision and efficiency. This advanced technology provides highly accurate results, ensuring that every car bodywork services and repair is carried out with meticulous care. Ultrasonic gauges send sound waves through the material, measuring its depth or thickness without any physical contact, which eliminates potential errors caused by human handling.

This non-invasive method is particularly beneficial in vehicle body shops where precision is key. It allows for quick and consistent measurements, streamlining the inspection process. By adopting ultrasonic thickness gauges, car repair shops can enhance overall efficiency, reduce the risk of human error, and ultimately provide higher quality services to their customers.

Versatile Applications and Material Compatibility

Ultrasonic thickness gauges offer a versatile range of applications across various industries, from automotive to manufacturing. Their non-destructive testing capabilities allow for accurate measurements of material thickness without damaging the surface, making them invaluable in auto maintenance, collision repair, and automotive body work. These tools are particularly useful for quality control, ensuring that components meet specific standards before assembly or during production.

The compatibility of ultrasonic thickness gauges with a wide array of materials is another significant advantage. Whether dealing with metal, plastic, or composite structures, these gauges provide consistent and reliable results. This material compatibility makes them indispensable in intricate manufacturing processes, where precision and consistency are paramount. In industries like automotive, where lightweight materials are increasingly used to enhance fuel efficiency and vehicle performance, ultrasonic thickness gauges play a crucial role in maintaining structural integrity while adhering to stringent design specifications.

Ultrasonic thickness gauges offer a significant leap forward in measurement technology, providing non-destructive, highly precise, and efficient solutions for various industries. Their versatility and compatibility with diverse materials make them indispensable tools, replacing traditional manual methods. By embracing ultrasonic thickness gauges, businesses can enhance productivity, ensure quality control, and unlock new levels of precision in their operations.